Landoll SLT30AC / SLT35AC FORKLIFT

|

DREXEL SWINGMAST®

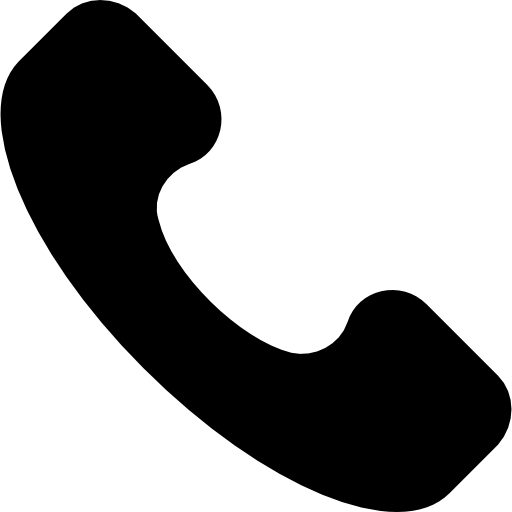

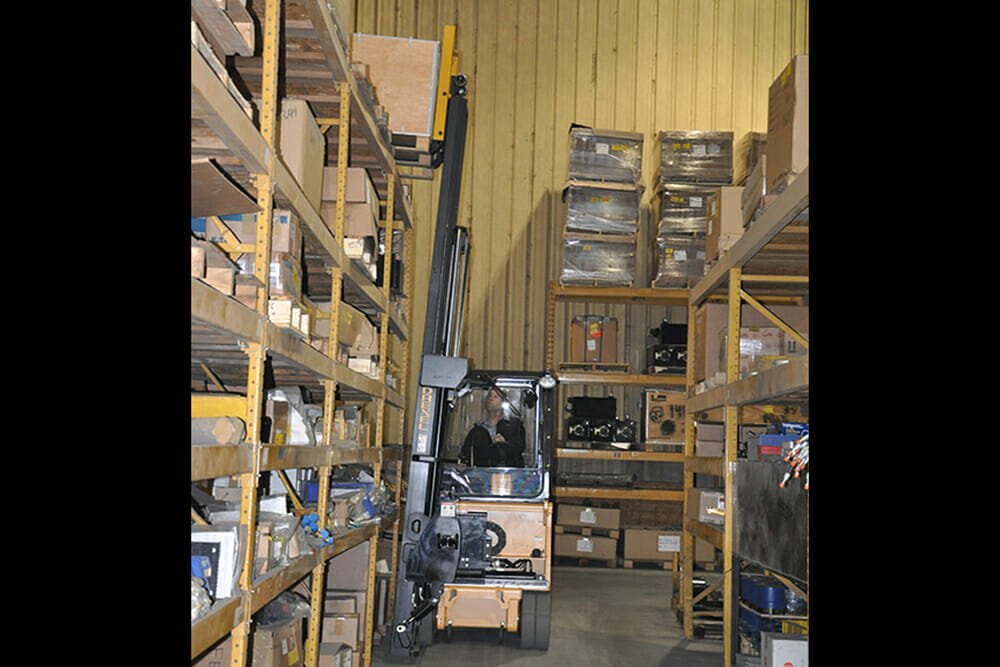

They are 3-wheel front/side loading VNA forklifts with a single smooth rubber rear-drive/steer tire and solid poly-front load tires. The front mast rotates 90° and has side shift of 20” (508mm), allowing stacking easily in Very Narrow Aisles. The Drexel SLT30AC and SLT35AC can work inside and outside on paved surfaces, and perform the jobs of a normal front-loading forklift (including loading and unloading highway trucks and containers, working in bulk storage, drive-in rack, push back rack, double deep and climbing steep ramps). The SLT range does the same jobs of reach and counterbalanced trucks in aisles over 50% smaller. The rear steering and drive allow turning in short-cross aisles, further increasing the storage density when compared to counterbalanced trucks. |

EXCEPTIONAL PERFORMANCE AND MANEUVERABILITY

EXCEPTIONAL PERFORMANCE AND MANEUVERABILITY

The SLT30AC and SLT35AC have fast lift/lower and travel speeds with a tight turning radius providing excellent maneuverability and productivity. The rollout battery compartment allows fast battery changes for multi-shift operations. High Visibility three and four stage masts are available for a wide range of applications including those with low overhead obstructions still requiring high lift heights. “Wire Guidance” is an option for this model allowing safe full-speed travel in the narrowest aisles. |

MAXIMIZES MATERIAL HANDLING PRODUCTIVITY

MAXIMIZES MATERIAL HANDLING PRODUCTIVITY

The versatile SLT30AC and SLT35AC forklifts replace conventional reach and counterbalanced forktrucks in standard warehouse operations. The unique design allows operators to use it as a counterbalance truck indoors or out, operate in very narrow aisles in warehouses, replacing reach and counterbalanced trucks that require much wider aisles. All tires on both models are 18″ (457mm) diameter and the truck has great underclearance for avoiding floor obstructions. |

| 3,000 lb. (1361kg) and 3,500 lb. (1588kg) Capacity at 24″ (600mm) Load Center Three-Wheel Design, Single Rear-Wheel Drive and Steering Provide Excellent Maneuverability and Traction Ergonomic Design for Exceptional Operator Comfort and Safety Single Joystick Controls Hydraulic Functions, Directional Control, Horn and Wire Guidance Electronic Steering Provides Smooth, Reliable, Long-Lasting Steering Control Interactive LCD Status Monitor (BDI with Lift Interrupt, Hour Meter with Service Monitor, Diagnostic Code Display, Input Device Calibration) |

| An Electro/Mechanical Parking Brake is Automatically Applied When Power is Turned Off or the Operator Leaves the Seat High Visibility Mast Allows Optimum Safety and View of Loads and Forks AC Traction and Hydraulic Motors Ensure Minimal Maintenance and High Efficiency High Efficiency Curtis AC Controllers Provide Trouble Free Operation 48 Volt Electrical System and Large Capacity Battery Compartment Optional Cold Storage Conditioned to -22°F (-30°C) The Adjustable Swivel Seat Improves Operator Comfort while Traveling in Reverse |

| Three-Wheel Configuration Rear-Wheel Drive and Steering High Visibility Mast (3 or 4-Stage) 90° Pivoting and Shifting Mast 48 Volt Electrical System AC Traction Control with Self-Diagnostics, Hour Meter and Battery Discharge Indicator with Lift Interrupt Adjustable Driver’s Seat (15° Swivel Seat) Safety Seat Switch – Cuts Power |

| Single Joystick Control Lever Parking Brake, Electric, Mechanically Applied, Electrically Released Hydraulic Service Front Wheel Brakes AC Hydraulic Pump Control Type “E” Construction Electronic Power Steering Automatic Return –to– Neutral Seat Belts |

| SB 350 Blue Battery Connector Key Switch Covered Battery Compartment Battery Compartment Rollers Cushion Rubber Drive Tire (1) Polyurethane Load Tires (2) Horizontal Fork Indicator Overhead Guard Load Backrest Horn |