ID # 34913709

Landoll 2400 SERIES WEATHERPROOFER (WP1)

Call for Price

Overview

Specifications

features

specifications

Documents

PRACTICAL TILLAGE ECONOMICS

PRACTICAL TILLAGE ECONOMICS

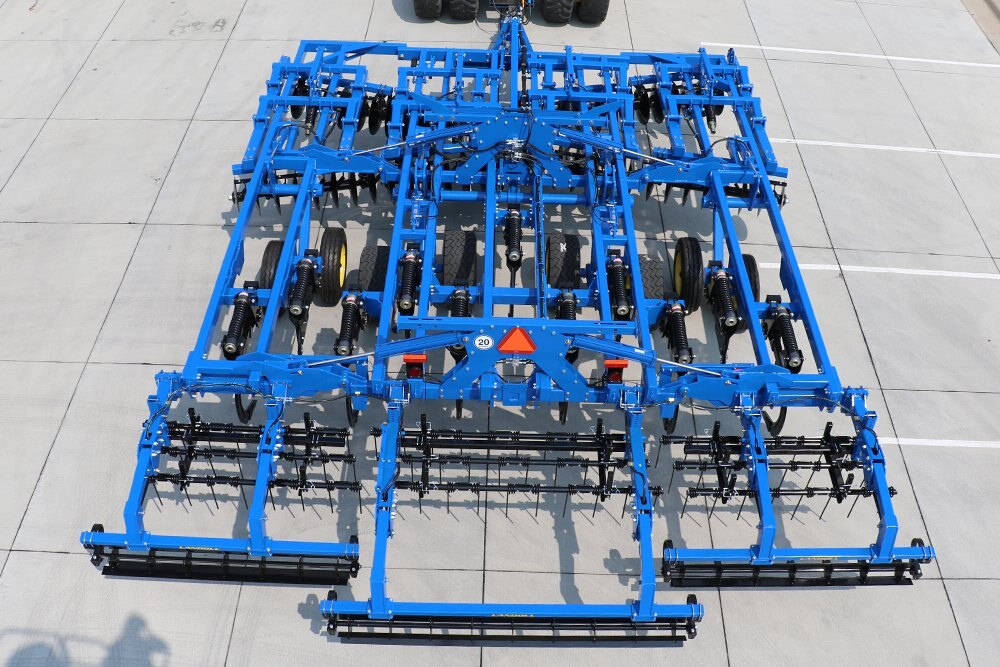

The Landoll 2400 Series Weatherproofer 1 (WP1) is at the top of its class when it comes to design, performance, and soil management. The combination of parabolic auto-reset shanks and tandem disc gangs provides accelerated residue decomposition, improved soil tilth, and conditions the soil for maximum water intake. The result is maximizing yields and improving profits. |

SIMPLICITY IN PRIMARY TILLAGE

SIMPLICITY IN PRIMARY TILLAGE

High yielding crops produce high levels of residue; primary tillage tools have to be able to manage this residue effectively. The simplicity of the WP1 and the ease of adjustment allows this series to perform up to its expectations every time. Single point depth control sets the depth of the entire machine. Consistent depth is maintained, even in wet conditions, with walking tandem axles and large flotation tires. |

SIZES TO FIT

SIZES TO FIT

Landoll has designed the 2400 Series in sizes to fit a wide variety of operations. Available in 6 shank rigid models, 7 & 9 shank folding models, and 11 & 13 shank 3-section folding models, the basic configurations are the same. Tandem offset disc gangs located upfront cut, size, and blend the residue with auto-reset parabolic shanks following to facilitate soil management and compaction control. 24” shank spacing on all models provides ultimate fracturing of soil profiles to allow water and oxygen to enter into the growth environment. Optional rear leveling devices are available to customize the final field finish. |

|

THE LANDOLL WAY

Landoll’s solid reputation of building quality tillage equipment is built into every 2400 Series WP1. Precision, laser cut frame components embrace the technology of robotic welding to its fullest. Durability is built-in, not added on. Incorporation of UHMW polymer in the lift axles provides a maintenance-free feature that eliminates daily greasing. Trunnion mount bearings that are cushioned by c-flex mounts are used throughout the disc assemblies and are covered by a 3-year warranty. Heavy-duty coil spring auto-reset shanks allow 3,000 lbs. of point load with a 14” trip height. The self-leveling hitch and the single point depth control add to the list of items that extend the reliability of the WP1 beyond the competition. |

Features

| Laser Cut, Robotically Welded Frame 5 1/2” Lift Axles with Maintenance-Free Lift System Walking Tandems on All Sizes Slip-In Spindles 340/60R x 18, 445/50R x 22.5, 295/75R x 22.5 Tires (Model Dependent) Self-Leveling Hitch with Manual Adjustment Cast Single Lip Hitch Cat. IV Single-Point Depth Control 24” or 26” Disc Blades Spaced at 10 1/2” 15 Degree Gang Angle Front |

| 1 3/4” Gang Bolt Trunnion Mount Bearings C-Cushion Bearing Mounts Overlapping/Staggered Offset Tandem Disc Gangs Staggered Shank Arrangement Auto-Reset Shanks with 3,000 lb. Point Load Variety of Points Available Adjustment/Maintenance Wrenches Blue Powder Coat Paint Safety Warning Lights |

Model

2400

Category Name

Agriculture

Year

2024

Sale Type

New

Manufacturer

Landoll

Quantity

0