Kuhn - 4100 Series

|

|

|

Specifications

|

Model |

4100 Series

|

Year |

2022

|

Sale Type |

New

|

|

Manufacturer |

Kuhn

|

Quantity |

0

|

Manufacturer Qty |

0

|

|

Price |

Contact for price CAD

|

|

|

|

|

Description

|

|

|

KUHN Knight 4100 Series 4-auger mixers are designed for small- to mid-sized cattle operations with features to provide reliable, efficient and affordable mixing. Whether you’re feeding a higher roughage dairy ration or a feedlot ration with higher levels of grain and byproducts, you can tailor your machine with features and options to best meet your needs. The drive system, undercarriage, box construction and weigh bar system have outstanding serviceability and reliability. The overall superior mixing performance of this machine stands out from the competition. You get genuine KUHN Knight quality with an innovative and streamlined design, durable components and a rugged build to help ensure reliability and long life.

|

|

|

|

MODELS

|

|

|

|

EQUIPMENT

|

Equipment

|

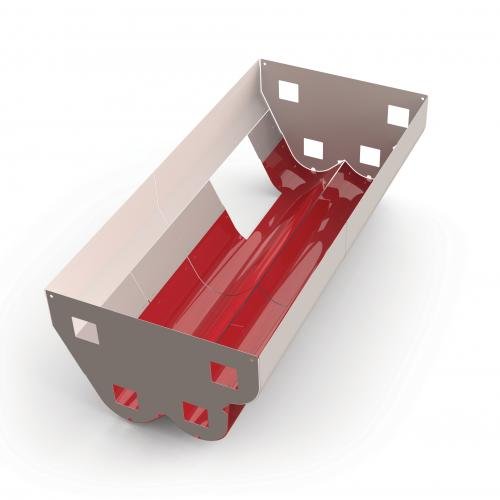

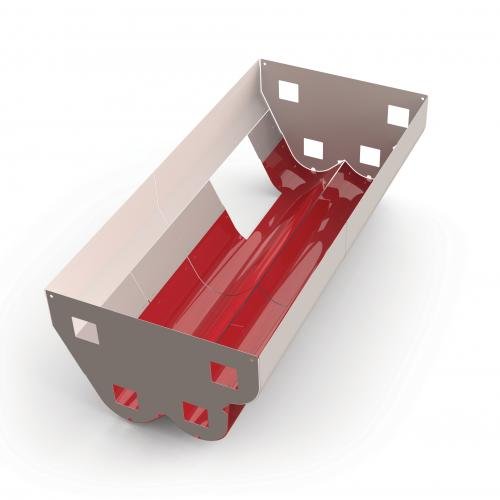

Partial or Full Stainless Steel Liner Partial or Full Stainless Steel Liner

The partial liner covers the most critical wear areas in the mixer and provides added protection and longer life. The full liner completely covers all of the high wear areas for unmatched dependability and long service life.

|

|

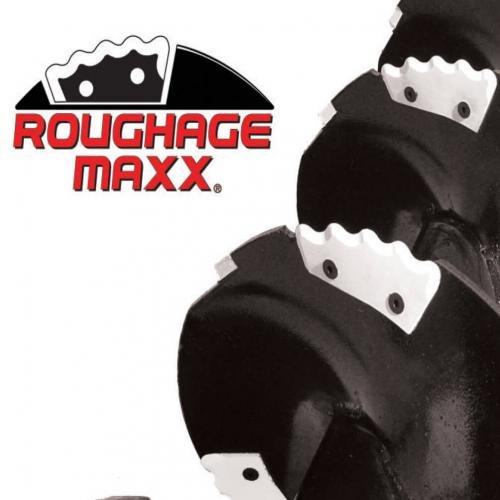

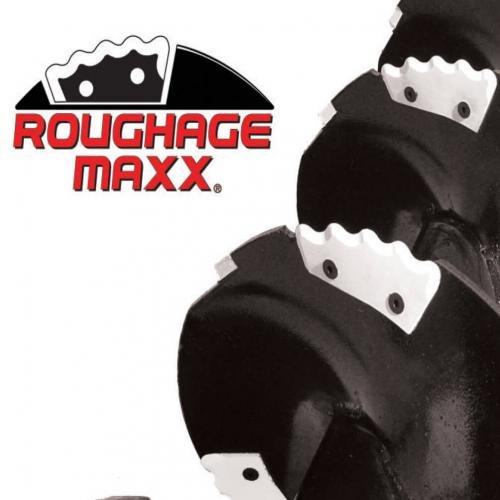

Roughage Maxx® System Roughage Maxx® System

The Roughage Maxx® System incorporates scalloped knives on the lower auger to maximize hay processing. The knives provide a more consistent particle length and more even blending. The result is a more uniform and palatable ration with reduced sorting for improved feed efficiency.

|

|

Capacity Belt Extension Capacity Belt Extension

A belt extension, added to the top of the mixing tub, increases capacity by about 10%. It also improves hay containment, and rubber construction is durable and pliable for long life.

|

|

Scale Systems Scale Systems

Different scale brands, models and options are available for all types of operations, ranging from the very basic to high-end feed-tracking programs that use a remote scoreboard display. Optional remote indicators are available for placement that will allow easier viewing.

|

|

|

YOUR BENEFITS

|

Your_benefits

|

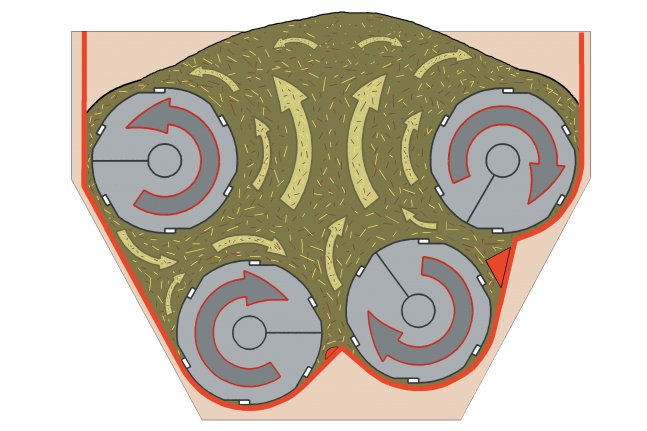

The Botec® Advantage

A Quality Ration and Complete Cleanout A Quality Ration and Complete Cleanout

A Quality Ration and Complete Cleanout

The raised lower right auger configuration, along with the close tolerance between the auger flighting and the auger troughs, results in a fast and complete cleanout. The offset upper right auger in combination with the raised lower auger requires less horsepower and provides a faster mix time.

Mix Full or Partial Loads Due to the cross-mixing action of horizontal auger mixers, Botec TMR mixers can properly mix batches that fill only a portion of the mixing tub providing you with the versatility to mix any size ration.

Even, Consistent Discharge

The close auger tolerances and raised lower auger design provide a fast, consistent discharge from beginning to the end of unloading. This results in even feed placement across the entire length of the bunk without a delay for mixer cleanout.

|

|

Splined Auger Shafts Splined Auger Shafts

Splined auger shafts allow a strong, reliable torque transfer and provide easier sprocket alignment and maintenance.

|

|

Competitive Mixers Competitive Mixers

Having parallel lower augers creates more force between the augers without increasing mixing capability. Parallel augers also do not transition the feed from right to left as well as if the right auger was raised. This design leads to slow, incomplete cleanout, decreases the mixer's processing ability and increases the horsepower requirements.

|

|

Simple, Dependable Drive

Heavy-Duty Rear Drive Heavy-Duty Rear Drive

The reliable heavy-duty roller chain drive runs in oil and has spring-tensioned poly idlers for long life.

|

|

Nylon Auger Bearings Nylon Auger Bearings

Reliable, externally mounted nylon bearings provide simple maintenance with reduced sensitivity to contamination.

|

|

Discharge Door & Linkage Discharge Door & Linkage

Large door openings allow for better ration flow and faster feed delivery. The discharge door frame is more rigid and less complex for dependable day-in and day-out operation.

|

|

4-Point Weigh Bar System 4-Point Weigh Bar System

Four-point weigh bar system comes standard as a cost effective and simple weighting system, yet still maintains 99.5% accuracy.

|

|

Tailor Your Machine

Multiple Discharge Options Multiple Discharge Options

To best suit your feeding needs, you can choose from a slide tray, chain and slat conveyor or a 3-auger discharge to be equipped on your 4100 Series mixer.

Slide Tray

The side discharge slide tray has simple hydraulic controls and helps guide feed further away from the tire path. Magnets are standard on slide tray.

Chain and Slat Conveyor

Rugged chain and slat conveyor options provide the ultimate in durability and long life. Heavy-duty components ensure reliable service and multiple conveyor length options offer unmatched flexibility to match different feeding situations.

3-Auger Discharge

The 3-auger discharge allows adjustment for feeding into higher bunks. It has a simple, hydraulic drive that provides smooth, even discharge. Long lasting, poly chute liners help prevent rust and limit wear. The 3-auger discharge comes standard with fixed tip-off and built-in magnets.

|

|

Trailer & Truck Models Trailer & Truck Models

To suit your operation’s needs, KUHN 4100 Series mixers are available in a trailer or truck-mounted configuration.

Trailer models are the most popular configuration as they are the most economical and versatile. Being detachable allows the tractor to be used elsewhere on the farm when not in use for feeding.

Truck-mounted models are a suitable option for those that have to feed cows at several different locations, with large travel distances. This option allows a feeder to quickly get from the mixing location to the feed bunk and back again.

|

|