Kuhn - SLC 141 TRAILER

|

KUHN Knight SLC 100 Series ProTwin® Slinger® commercial manure spreaders set the standard for fast, efficient spreading. Maximize your productivity and performance with our large-capacity truck-mount or trailer models. The unique twin-auger design and exclusive v-body construction allow the Slinger to handle the widest variety of materials compared to any spreader on the market. Complete adjustability of the wide discharge improves material breakup for more consistent, even spreading. New hammers are designed for less wear and longer life. These spreaders provide the ideal combination of efficiency, versatility, and rugged durability to give you maximum return for your equipment dollars. If you need one machine to handle all of your diverse spreading needs, look to the SLC 100 Series ProTwin Slinger manure spreaders. |

|

The First of Its Kind, ProTwin® Design

The raised, right auger moves material rearward to keep the load level. The left, lower auger moves material forward to continuously feed the discharge door.

//

Consistent Flow to the Discharge

//

Eliminates Bridging |

|

The continuously welded V-body tank will hold both wet and dry materials. From soupy manure, to semi-solids, separated solids, compost, bedding pack, mulch and many other materials, the ProTwin® Slinger® can fit the needs of your operation. |

|

The heavy-duty undercarriage is built for dependable service under heavy use in the toughest conditions, including hauling sand-laden manure. All SLC models come standard with tandem axles. |

|

Fast Unloading with Consistent Spread Pattern

Enhanced Hammer Design

Enhanced Hammer Design

A new hammer design features more wear surface on the bottom edge to extend hammer life. The new fully adjustable shroud helps decrease wear, extending life even further. Nylon bushings and washers help prevent premature wear to the bolts, hammers and hammer shaft ears. |

|

All SLC 100 Series commercial models feature a wide, 18-hammer discharge for fast, efficient unloading of all material types. The increased discharge of the SLC 125 and 132 offers a 20% increase in unloading capacity compared to a 15-hammer discharge. The wide, aggressive hammers effectively shear material and provide a consistent, even spread pattern. |

|

The two-piece shroud and sill design provides full adjustment for optimal setting of the clearance between the shroud/sill and hammers. Maintaining the proper clearance enhances the shearing performance of the hammers to provide a more consistent material flow and more even spreading. The sill on the SLC is also easily replaceable, making maintenance simple. Independent adjustment of the shroud (front) and sill (rear) allows you to maintain the proper clearance around the full internal radius. This helps ensure that material is more effectively carried on the faces of the hammers for decreased wear and a lower horsepower requirement. |

|

The hydraulically adjustable deflector provides the ability to conveniently regulate the spread pattern from the tractor seat while spreading. This allows close control of the spreading width for accurate nutrient placement. The deflector stores in the down position and although it is not water tight, it completely closes off the discharge area to help prevent material loss during transport. |

|

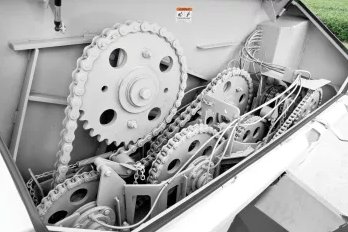

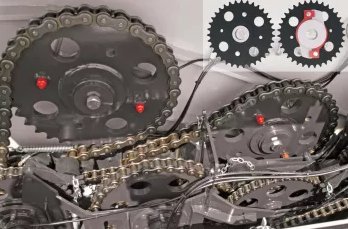

Heavy-Duty, Low-Maintenance Drive

The durable, heavy-duty drive requires minimal maintenance and provides years of reliable service. All rear chains and sprockets have been eliminated. The entire drive is now enclosed in the front oil bath which provides constant lubrication of the chains, bearings and sprockets. |

|

The drive of the SLC 100 Series manure spreaders incorporates individual shear protection for each auger. The shear bolts are conveniently located in the oil bath enclosure for easy access. They provide effective protection for the chains, sprockets, bearings and shafts against damage due to overload, wedging and obstructions. |

|

The three main drive shafts are fully welded and removable. This allows for easier service with no keys and set screws to hassle with during maintenance. |

|

Both augers feature upgraded shearbolt protection on the transfer paddles. Transfer paddles on the right auger deliver material to the left auger. The paddles on the left auger deliver material to the discharge. The paddles are also split for easy removal and replacement if necessary. |

|

The overrunning clutch on the hammer shaft allows it to rotate freely when the PTO is disengaged. This reduces backlash on the PTO and on the spreader drive components for less wear and longer life. |

| Download Brochure | Download |