Kuhn - VTC 200 Series

|

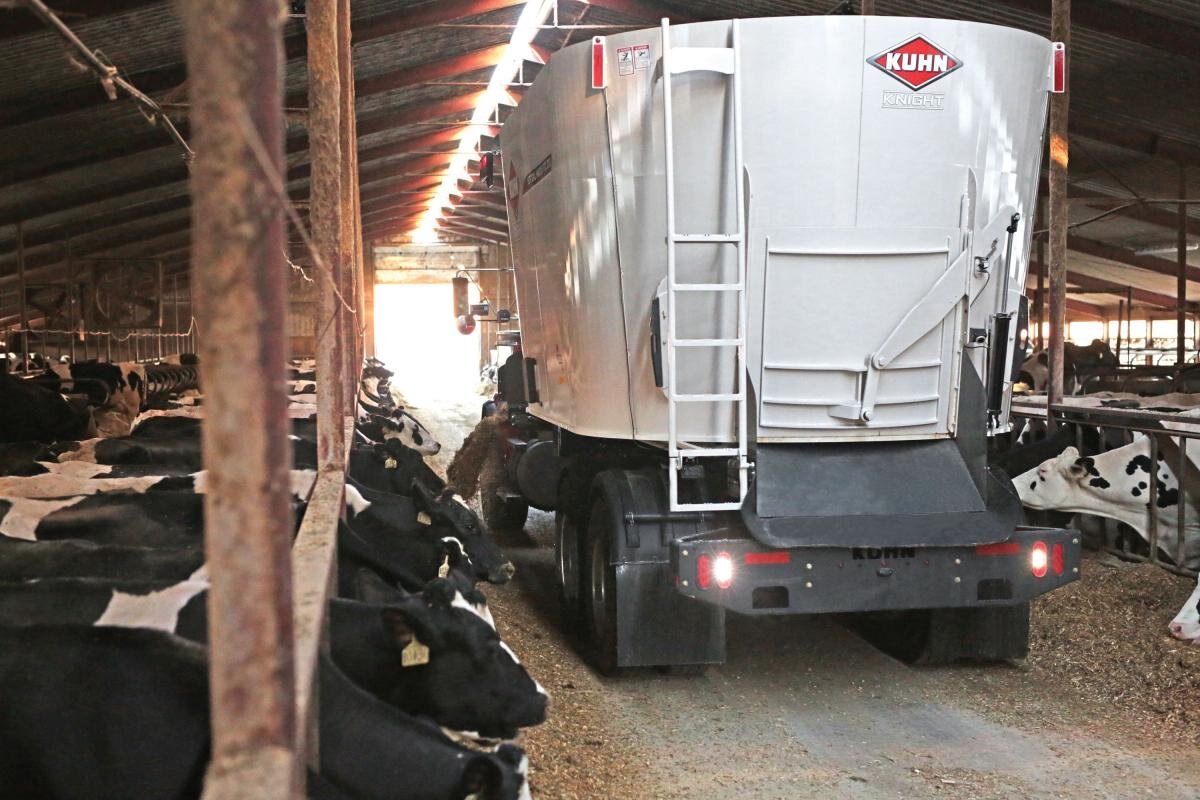

KUHN Knight VTC 200 Series Vertical Maxx® twin-auger commercial mixers are built to the heaviest specifications in the industry to ensure a quality mix day-in and day-out, even in the most extreme-duty cycles. With commercial-grade components, stainless steel liners standard and the heaviest single-stage planetary gearboxes in their class, these mixers are built to withstand any feeding application and are designed to continue running around the clock. The VTC models are available in single- or tandem-axle trailer, truck mount and stationary configurations. For fast and thorough mixing, durability and long life, these mixers are an excellent choice for commercial operations. |

|

|

KUHN offers a 5-year prorated warranty on planetary and 2-speed gearboxes on all vertical mixers. KUHN also offers a 1-year warranty on all other machine components. |

|

A belt extension, added to the top of the mixing tub, increases capacity by about 10%. It also improves hay containment, and rubber construction is durable and pliable for long life. |

|

The flat, front conveyor option is simple to operate and offers convenient feeding from either side of the machine on trailer models. Hydraulic side shift is standard and gives you the ability to shift the conveyor a total of 16” from side to side for accurate feed placement. Either or both ends of the flat conveyor can be fitted with a hanging belt with magnets to catch small metal fragments. The hanging belt also helps to even feed flow off the end of the conveyor. A fixed tip-off, with magnets, can be added to catch small metal fragments present in the feed and help prevent hardware disease. |

|

An optional belt conveyor can be added for easy and consistent placement of feed at varying heights including the filling of mobile feed carts. The belt offers quiet operation and consistent feed flow. Belt conveyors are able to run steeper versus a chain and slat because you can run the conveyor faster, depending on the materials. The low profile sides allow the conveyor to fold up tighter to the machine for a more narrow transport width. An optional deflector helps with placement of the feed and provides an option for magnets. |

|

Different scale brands, models and option are available for all types of operations, ranging from basic to high-end feed-tracking programs. Optional remote indicators are available for placement that will allow easier viewing. |

|

The incline conveyor option is available with the choice of either right or left side unloading on trailer models. This option allows the flexibility for both floor feeding and feeding into bunks of various heights where a longer or higher reach is needed for precise feed placement. A fixed tip-off, with magnets, can be added. The magnets work to catch small metal fragments present in the feed and help prevent hardware disease. |

|

The side-discharge slide tray on the VSL & VT models has simple hydraulic controls and helps guide the feed further away from the tire path. Discharge magnets help catch metal fragments to prevent hardware. |

|

A rear commodity door is available on VT and VTC models. The large opening provides fast discharge, even with high-roughage premixes. A discharge tray is included on truck models to direct material flow for clean, accurate feed placement. |

|

Optional side conveyors provide the ultimate in durability and long life. Heavy-duty components ensure reliable service, even in extreme use conditions. Multiple conveyor length options offer unmatched flexibility to tailor the discharge to your needs. A fixed tip-off with magnets can be added to catch small metal fragments present in the feed and help prevent hardware disease. |

|

Superior Feed Movement

Cone-style augers provide superior feed movement for faster, more complete mixing and processing. The smooth, continuous auger flighting (1) creates a rolling feed action that improves mixing. The top cover of the auger has a steep angle to aid in bale movement when processing round bales and to prevent feed from sitting on top of the auger between mixes. The swept back, bolt-on kicker (2) provides a fast and even discharge. The new kicker mount design is stronger and built to withstand the harshest resistance. Each lead flight is equipped with a cast iron scraper (3) that pulls material away from the tub walls into the auger for a better overall mix. Both the kicker and scraper are bolt-on attachments, making replacement very easy to save you precious time. |

|

Large, 15” or 20”, replaceable hay cutting knives are available to best handle the material to be processed. The knives have two positions to adjust the aggressiveness of the knife angle. Versatility of knife length, angle and position allow for an optimal setting with a wide variety of ration ingredients. // A: Knife set in for slicing and cutting // B: Knife set out for grabbing and tearing |

|

Straighter sides, smoother curves and steeper baffles help promote a fast, complete mix for a fluffy, palatable ration. No preprocessing or special loading is required for round or square bales making it easy to load and use. Faster auger speeds also provide quicker, more complete cleanout. |

|

The adjustable hay stops provide flexibility in processing to provide you with the cut length necessary to reach the optimal nutritional value you’re striving for. This adjustability makes hay processing more efficient and helps minimize overprocessing. |

|

For unmatched feed flow, these mixers feature the largest discharge door available in the industry. The discharge linkage allows for rapid opening and closing of the door. |

|

Simple, Dependable Drive

Patented Split Drive

Patented Split Drive

The patented drive system on the VTC 200 Series trailers consists of a 2-speed, split-drive gearbox, two planetary gearboxes and two torque-disconnect PTOs. This system provides reliable performance and long service life with a simple and quiet design.

//

2-Speed Split-Drive Gearbox

The 2-speed, split-drive gearbox provides the flexibility of high and low speeds without adding another gearbox. It allows for a lower horsepower and easier starting speed (28 rpm in low) while also having a high speed for fast mixing and more complete cleanout (41 rpm in high). The gearbox can be shifted manually on the machine or with an in-cab electric shift option for operator convenience.

//

Heavy-Duty Gearboxes

The twin planetaries are designed to provide dependable performance and long life. The drive systems allow the use of single-stage planetaries, which produces far less heat for easier cooling. VTC planetary gearboxes are the heaviest and strongest in this mixer class and are designed to run up to 24 hours a day.

//

Torque-Disconnect PTOs Two automatically resetting torque-disconnect PTOs provide independent protection for each planetary. This helps guard against obstructions encountered by each individual auger, ensuring reliable service and longer life. |

|

Easily pull the planetary from the top of the mixer for improved and easier service. This easy accessibility is especially helpful for truck mount models as it does not require dismounting the mixer from the chassis. |

|

VTC 200 Series truck mounts now feature an inline planetary, making a simple, straight turck drive compared to the 2-speed, split drive on the previous models. The removal of the 2-speed gearbox allows for the planetaries to be dropped down further within the truck frame, lowering the overall loading height of the front door truck mixers by 4 inches! A self-compensating drive with a new variable displacement hydraulic motor automatically maximizes auger speeds according to the torque on the augers. This system provides the convenience and flexibility to run the mixer at a wide range of speeds to meet processing, mixing, and clean-off needs. Front Engine PTO (FEPTO) or Rear Engine PTO (REPTO) configurations are available in both 12-volt and 24-volt systems. A cooling & filtration system works between the hydraulic pump, reservoir, fans, and planetary gearboxes to constantly cool the oil throughout the system. The continuous synthetic oil flow goes in a complete loop from pump to cooling system to hydraulic block and back to pump. When oil comes out of the motor, a small amount of oil filters to the planetary gearboxes to cool planetary oil as well. With running this cooling and filtration system, we do not require a break-in oil change, this lengthens out the service interval to 3,500 hours. |

|

New KUHN truck mount controls provide an ergonomic advantage for vertical mixer control. Operators can control both the augers and discharge with a single joystick. For ease of maintenance an external fuse box provides easy access to fuses and relays. Auxiliary power capability is available in the new wiring harness, an easy power source for scale indicators. |

|

Built to Last

The completely welded body provides superior strength and durability for long life. The heavy-duty, reinforced floor and body help ensure dependable service and long life. |

|

The straight, single axle is ideal for farms with paved surfaces and sharp turns. The walking, tandem bogie is recommended for farms with uneven terrain. Both axle systems are located under the tub for decreased tread width to keep the tires from running over the feed. |

|

DuraMix extended wear components help ensure dependable service and long life, even under the heaviest-use cycles. These include standard stainless steel liner sides, higher carbon steel on the baffles and high-wear augers for all KUHN Knight VTC 100 Series mixers. For additional wear protection, optional baffle liners are also available. |

|

A thick floor helps to maintain solid structure of the mixer throughout many hours of mixing. On VTC models there are two floor options, a standard 1” thick, mild steel floor, or an optional ¾” thick, mild steel floor with a ¼” stainless steel liner. Each floor option is dependable, reinforced, and built for heavy loads and long life. |